Electric Vehicles

Innovation and electrification

From enhancing wear resistance and corrosion protection to improving thermal management and optimizing charging performance, our surface finishing solutions are proven to drive performance. Trusted by leading Original Equipment Manufacturers (OEMs) worldwide, we are partnering with clients to optimize electric vehicle performance and appearance.

EV Thermal Management

Controlling the thermal energy created by semiconductor power devices is critical within EV assemblies. Copper and aluminum heat sinks transfer this thermal energy and must allow for soldering and sintering while withstanding contact with glycol coolants. Our industry-leading electroless nickel technology enables uniform metal distribution, making it an excellent choice for plating complex geometries and creating a barrier coating on all sides of the heat sink.

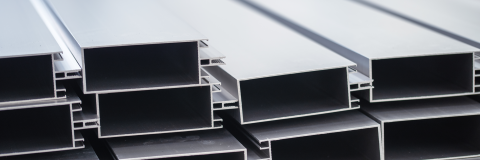

EV Battery Cases

Battery cases are most commonly made of aluminum or steel. We have chemistry to meet every need on the interior and exterior surfaces of the case. Our finishing processes deliver optimized surface conditioning, industry-leading corrosion protection, adhesion for coatings, and unmatched uniformity, all at reduced operational costs.

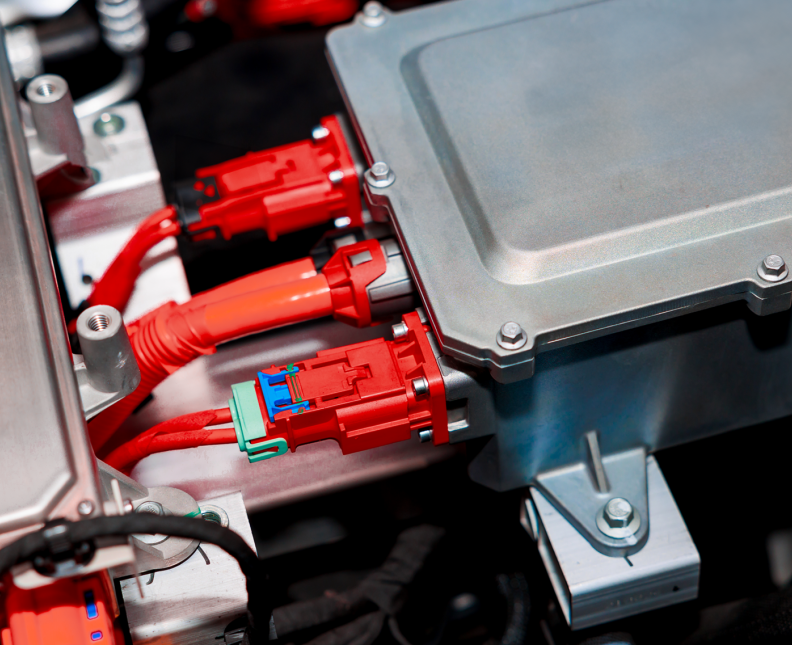

Electric Vehicle Connectors

EV connectors require low electrical resistance and durability to enable efficient charging for the life of a vehicle. With a solutions portfolio that includes both electroless nickel coating for copper and aluminum and silver and tin plating for low electrical resistance, we offer unmatched durability and functionality for connectors and interconnect components.

Safety Critical Components

Specified by leading OEMs and Tier 1s, our solutions for safety-critical components, including braking systems and fasteners, are designed to deliver unrivaled consistency and the lowest cost of ownership. With an array of finishing solutions for calipers, pistons, aluminum surfaces, and steel fasteners, our solutions are designed to mitigate risk and maximize performance throughout the life of a vehicle.

Electric Vehicle Busbars

Copper and aluminum EV components require enhanced durability and electrical resistance. Our tin and silver plating solutions deliver excellent solderability and protection for copper busbars, while electroless plating using NiKlad and ENOVA EN provides uniform coating with the highest productivity.

EMI Shielding in EVs

As the material of choice for shielding applications, engineered plastics need surface protection to avoid the penetration of electromagnetic waves. Our metal plating solutions deliver this protection while also meeting weight, mechanical, and shielding requirements. With a variety of multi-layer stack and etching options available, our solutions can be customized to meet any unique shielding requirement.

Frequently Asked Questions

- What role do surface finishing solutions play in electric vehicles (EVs)?

-

Surface finishing solutions provide more than aesthetic beauty to electric vehicles—they play a critical role in functionality and durability. Surface finishing solutions protect various components including battery housings, exterior body panels, braking components, and motor parts. Surface finishing also improves thermal management and electrical conductivity, contributing to the longer lifespan, improved range, and better performance of the vehicle. And yes, improved aesthetics.

- How do surface finishes benefit EV connectors?

-

Surface finish influences a vehicle’s ability to regulate temperature, affecting heat dissipation and absorption as well as conductivity. A good surface finish improves overall battery efficiency and lifespan, improving the performance of electrical components of the vehicle.

- What are the benefits of surface treatments for safety-critical EV systems?

-

Corrosion-resistant coatings and surface treatments protect the components of electric vehicles from rust, degradation, corrosion, and other performance-reducing issues. They safeguard critical components, acting as insulation against electricity and heat, while also performing as an eco-friendly option that minimizes waste and improves durability.

Coatings can protect battery housings, stop cooling systems from overheating, and reduce the risks that compromise a vehicle during normal ownership wear and tear.

- What is EMI shielding, and why is it important for EVs?

-

Electromagnetic interference shielding (EMI) uses conductive materials to protect electronic components. EMI can disrupt the functions of electric components in EVs, and is a crucial component because of the high concentration of electrical systems present within the confined spaces of these vehicles. Without EMI shielding, interference can cause critical malfunctions in sensors, driving controls, and communication networks.

- Why is busbar surface finishing important in EVs?

-

Busbars are solid bars of metal, typically copper or aluminum, that are used to connect points in a high-power electrical transfer/distribution circuit. EVs are essentially a mass collection of discrete electrical circuits and batteries and busbars play a crucial role in ensuring everything works as planned. By connecting the battery, onboard computer, and key components, busbars solidify a network that relies on precise engineering and quality materials.