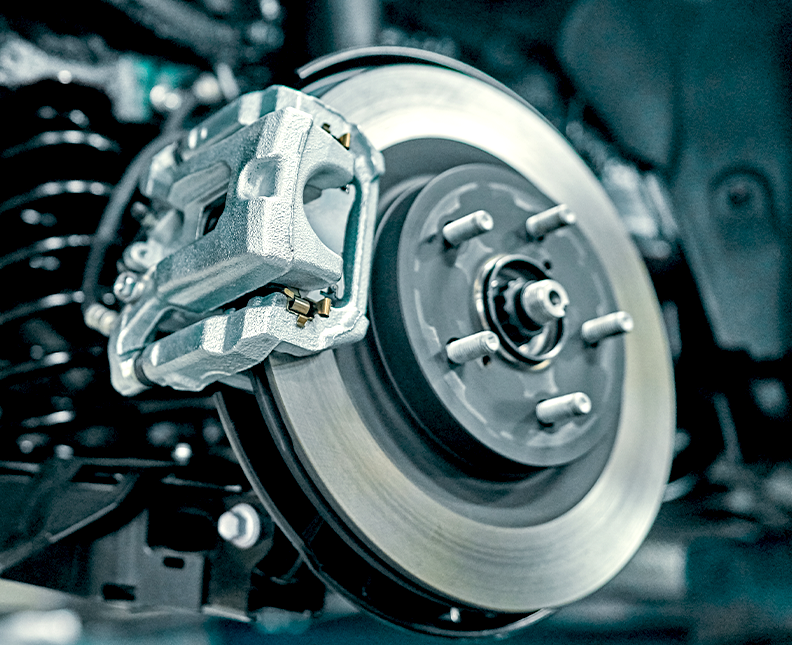

Brake systems

Brakes that go the distance

We pride ourselves on developing tailored solutions for practical brake system components. Our proactive and forward-thinking approach enables us to respond quickly to ever-evolving industry demands and legislative requirements, developing industry-leading solutions for safety-critical components.

Technology Overview

- Surface preparation

-

Grey cast iron containing high levels of carbon presents special requirements for pre-treatment. Removing oils, oxides, and carbon residue is a critical step in achieving the desired corrosion resistance.

MacDermid Enthone’s specialized pre-treatment systems for both cast iron and cast aluminum have been designed to prepare a clean and active metallic surface. The first stages remove oils from the porous substrate. After removing oxides and residuals from the casting process, the next stage ensures the surface is smut-free with support from ultrasonic and electrolytic cleaners. The surface can now be activated for the subsequent plating process.

- Zinc & zinc alloy plating

-

The choice of zinc plating process will depend on the specific application and corrosion resistance requirements.

Depending on the corrosion resistance requirements either an acidic zinc or zinc nickel process is chosen.

Our Kenlevel zinc and ZINCROLYTE™ Ni V zinc-nickel processes are specially formulated for cast iron finishing, providing optimized initiation and coating distribution on this specific substrate material. Complemented by our Tier 1 approved post-treatment, including specialized sealer solutions, these processes provide unmatched performance and reliability.

- Hard chrome

-

Wear resistant chromium finishes are available for brake piston finishing, with the majority being finished with ANKOR 1111. This process provides crack-free chromium coatings with a corrosion resistance of up to 96 hours in salt spray, and wear resistance from 700 to 750 HV0.1 hardness. No hydrogen is transferred into the coating or substrate from ANKOR 1111.

- Electroless nickel

-

Our industry-leading electroless nickel processes meet automotive specifications for wear resistance and corrosion protection as required for brake pistons.

- Anodizing and Conversion Coatings

-

Next to iron, aluminum is the most widely used engineering metal. We offer advanced conversion layers for paint adhesion and corrosion protection, as well as anodizing processes for base metal protection and coloring.

Anodizing cast aluminum brakes to achieve superior aesthetic and corrosion performance can be done by using our CASTELOX processes. This additional treatment increases corrosion protection and wear resistance while improving overall appearance, delivering an attractive bright finish that displays vivid colors.

Cobalt-free trivalent chromium conversion coatings such as IRIDITE™ TCP, provide additional corrosion protection to anodized surfaces when used as a sealing agent. The IRIDITE system can also be used a base for powder paints, lacquers, or rubber bonding.