All modes of transport, including bicycles, internal combustion engine (ICEs) cars, and electric vehicles (EVs), rely on energy transformation. Bicycles depend on a rider’s muscles, fueled by glycogen, to generate torque through the crank arm. ICE cars convert the combustion of liquid fuel into torque on the crankshaft. In contrast, EVs use electric motors to transform electrical energy into torque acting on the motor’s central shaft.

Although energy transformation effectively propels vehicles, it’s never 100% efficient, with heat being the most common byproduct of this inefficiency.

Surprisingly, humans are only about 25% efficient and must sweat to shed excess heat while exercising. ICE vehicles offer slightly better efficiency, peaking at around 40%. But they still lose significant energy as heat through exhaust gases. They also require extensive cooling systems to keep pistons and cylinders from melting. In comparison, EVs exhibit far greater efficiency, converting 75 to 90% of their electrical input into mechanical output. However, despite their high efficiency, EVs also generate waste heat that must be managed effectively.

Heat sources in EVs

In EVs, various energy transformations generate heat and require careful management. Some of these processes include:

- High to low-voltage dc conversion: Essential for running peripheral systems.

- Ac to dc conversion: Occurs while onboard chargers (OBC) are charged.

- Battery charging and discharging: This process produces heat, especially during rapid charging.

- Dc to ac conversion: Inverters transform battery dc into ac for traction motors.

With these processes in mind, next let’s discuss how thermal management is related to battery cells and inverters — which are the most significant sources of heat in EVs.

Managing battery cells

Lithium-ion batteries, most EVs’ backbone, move lithium ions between the anode and cathode. Although the Coulombic efficiency measures how much charge is returned to a battery after a charge cycle compared to how much charge was put in, of these batteries can exceed 99%, losses in the form of heat are inevitable. Rapid charging or discharging can exacerbate heat generation, posing a challenge for thermal management, mainly because battery packs often comprise thousands of individual cells.

Optimal battery performance occurs within a temperature range of 5° to 40° C. In extreme climates, particularly cold environments, managing heat becomes crucial. The thermal management system must facilitate heat removal when batteries overheat and heat addition to maintain optimal operating temperatures.

Traditional ICE cooling systems, which use liquid cooling, have been adapted for EVs. With its high heat capacity, water serves as an excellent heat transfer fluid. This adaptation is complex due to the different heat generation dynamics. In ICE vehicles, a limited number of cylinders must be cooled. However, in EV battery packs may contain thousands of cells, each generating heat unevenly.

Two common approaches are:

1. Cold plates are large, flat plates containing channels through which a heat exchange fluid circulates. These plates are positioned above or below the batteries and may incorporate specialized Thermal Interface Materials (TIMs) to enhance heat transfer. Cold plates effectively manage heat, especially for battery packs using cylindrical cells, which often exhibit anisotropic heat dissipation.

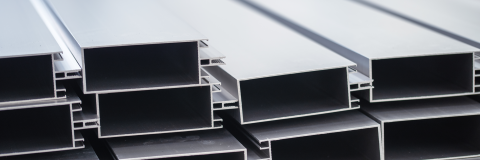

2. Cooling ribbons are hollow aluminum channels that snake around individual battery cells. This method, favored by companies like Tesla, increases surface contact with each cell, allowing for better thermal management. Liquid coolant is pumped through these ribbons to adjust cell temperatures as needed; this design has proven effective and durable.

Addressing battery cooling issues

As battery technology advances, the need for efficient cooling systems will become more prevalent. A current limitation is the contact area — cold plates, and cooling ribbons have limited contact with the surface of battery cells, constraining heat transfer.

Another limitation is liquid cooling. As these systems must effectively absorb heat and release it to a cooler environment, they rely on a temperature differential for efficiency. Immersion cooling presents a potential solution wherein a liquid coolant fully surrounds battery cells, maximizing surface area exposure. However, implementing water-based coolants poses safety risks, so current systems often employ exotic, non-flammable solvents, which can be costly and less efficient than water.

Phase change cooling is another option to improve thermal management. This method uses the energy required to transition a substance from liquid to gas, offering significant heat absorption capabilities. While phase change cooling from solid to liquid is common in low-power applications, expanding this concept to include liquid-to-gas transitions could yield even greater heat management efficiency. Unfortunately, the cost and toxicity of suitable liquids remain barriers to widespread adoption.

Inverter heat management

Significant heat is generated in addition to battery cells during the conversion of DC from batteries to AC for traction motors. This process occurs within the inverter, which consists of high-speed switches that regulate the alternating current’s cycle and amplitude. AC motors are favored for their efficiency and regenerative capabilities, allowing energy recovery during braking.

While modern inverters are efficient, they are not without limitations. Conventional systems operate optimally at temperatures below 75° C, while advanced silicon carbide (SiC) and gallium nitride (GaN) chips can withstand temperatures of 150° C or higher.

Effective thermal management for inverters involves careful design of the heat sinks to dissipate heat. Typically, heat sinks made from copper or aluminum absorb and transfer heat away from the inverter chips. These heat sinks must balance effective thermal conductivity with compatibility with the liquid coolant used in the system.

Adding nickel layers to the heat sinks has proven effective at providing corrosion protection on the liquid contact side of the heat sink. Additionally, these layers act as a solid base for the advanced chip attachment materials used to adhere inverter chips to the opposite side. When properly applied, the nickel layer also helps maintain compatible thermal expansion characteristics needed to support the system’s long-term reliability.

The future of inverter thermal management

Optimization of heat sinks on the coolant-facing and chip-attach sides is actively progressing. Researchers are developing more complex geometries to enhance coolant flow and increase surface area for improved heat exchange. Surface protection technologies are being adapted to support these advancements.

On the chip-attach side, efforts focus on improving or eliminating layers between the heat sink and the chip. Sintered materials, such as silver, are becoming increasingly popular due to their cost-effectiveness and performance compared to traditional solders. Additionally, the field of sintered materials is expanding to include copper, which may provide further valuable options for designers.

Summary

Thermal management is crucial to EV performance, particularly regarding battery cells and inverter systems. As the demand for increased range, power, and reliability in electric vehicles grows, innovative solutions to manage heat will be paramount. The evolution of battery and inverter technologies continues to pave the way for enhanced thermal management strategies, ensuring that EVs remain efficient and effective as we move toward a more sustainable transportation future.

Read the full article, available now at EV Engineering + Infrastructure