Renewable Energy

Future forward innovation

The renewable energy sector is continuing to grow, and energy providers are looking for supply chain partners that prioritize sustainability, environmentally conscious practices, and safety. We deliver sustainable surface finishing solutions for the next generation of energy exploration & production.

Wind turbines

Wind turbine energy systems often operate in harsh and exposed environments, making corrosion resistance a paramount requirement. Their materials must also have superior strength-to-weight ratios to maximize energy output while minimizing structural demands. These systems are designed to create power, and our zinc and zinc alloy coatings ensure that your systems stay strong, even in corrosive environments.

Solar power systems

Thermal stability and corrosion resistance is critical, particularly in concentrated solar power systems where components are exposed to intense heat, sunlight, and weathering. These systems require a high degree of electrical conductivity for efficient energy transmission, making materials like copper and aluminum invaluable in electrical grids and interconnectors.

Green hydrogen

When made using renewable energy sources, green hydrogen shows potential in decarbonizing industries, including transportation, contributing to a more environmentally friendly and sustainable energy landscape. As green hydrogen production, use, and storage grow, surface treatment will play a pivotal role in infrastructure development worldwide. Electroless nickel can be used to increase the corrosion and wear resistance of valves, piping, and storage vessels.

Technology overview

- Anti-corrosion coatings

-

Zinc, coupled with a trivalent chromium passivate, provides an exceptionally corrosion resistant and electrically conductive finish at an economical cost. The protection is largely the result of the zinc corroding preferentially to the steel, therefore extending component life.

MacDermid Enthone’s range of trivalent passivates are all hexavalent chromium-free. Cobalt-free systems are also available.

- Electroless nickel

-

Electroless nickel coatings play a crucial role in storing and transporting green hydrogen by providing a corrosion-resistant barrier for hydrogen containment vessels. This coating enhances durability, prevents hydrogen embrittlement, and ensures the integrity of storage systems, contributing to the safety and efficiency of green hydrogen production, storage, and transportation processes.

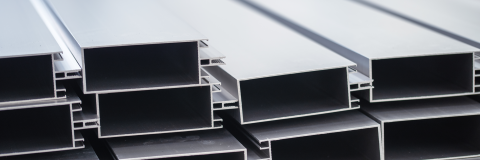

- Light metal finishes

-

Light metals, including aluminum, have wide use in renewable energy applications, such as solar energy structures, wind turbines, and hydroelectric power plants. In these applications, parts are subjected to harsh environments open to corrosion and physical wear and tear. Surface protection in these difficult applications is achieved using our state-of-the-art aluminum portfolio ranging from passivation to anodizing, extending the service life and durability of critical parts.